Sort of Paste

1. Sort by Functions : Conductivity, None conductivity

2. Sort by Usage : Dry Type, Curing Type, Plasticity Type

3. Sort by Work Process : Spray, Dipping, Printing, Rolling

Sort of Conductive Paste

1. Main Sort : Plasticity, None Plasticity

1) Plasticity : Lower temperature Plasticity(under 600℃), High temperature Plasticity(over 600℃)

2) None Plasticity : Room temperature Curing Type, Heating Dry Type, Heating Curing Type

2. Detailed Sort of Paste Functions : Paste for PCB, Paste for Chip Parts, Paste for RF Parts, Electrode for LTCC, Paste for Display.

1) Paste for PCB : Silver Through Hole Paste, Copper Through Hole Paste, Paste for Via Plugging, Paste for Jumper, Paste for Flexible PCB

2) Inner/Outer Electrode for Chip Parts : MLCC, MLCI, MLV, C/R, Chip NTC

3) Paste for RF Parts : Dipping, Printing, Spray

4) Electrode for LTCC : Inner Electrode, Outer Electrode, Via Fill

5) Paste for Display : Paste for Touch Screen Panel(Screen Printing, Laser Etching, UV Curing), Metal Mesh, Bezel Ink

6) Other : Paste for Solar Cell, Paste for Pressure Dielectric Substance, Paste for Piezo-electric, Paste for Ceramic thermistor

Sort of None Plasticity Paste

1. Room Temperature Hardening Type : In general, composed as 2 types of liquid(Main Substance / Hardening Substance), and mix it as regulated ratio to use.

2. Heating Dry Type : Use resins such as polyvinyl acetate, polyamide, Polyacrylic, polyester, nitrocellulose, and use it with film after volatilization of mixtures.

3. Heating Hardening type : Using a of epoxy, phenol, urethane and acryl mixtures, stable paste at room temperature.

Curing Type Paste

The function shall be achieved by the adhesion on the substrate and binding of Filler by cross linking

between resins.

Composed Elements of Curing Type Paste

1. Resin : Amorphous solid or semi-solid substance which affects the basic physical properties, is composed of organic compound and a derivatives.

2. Hardener : Cross linker compatible with Resin and additives, which affects the chemical reaction speed.

3. Filler : Metal substance(Ag, Cu, etc) which affects to liquidity and heating expansibility, heating conductivity, and conductivity.

4. Solvent : Substance which maintains certain level of viscosity and shape according to the work method and time.

Application Purpose of Curing Type Paste

1. It shall be applied to unstable adhered substance by heat and limited sustainability.

2. Curing Temperature : Heating hardening type is in general being made of over 90% crossing linking for 10-60minutes under the temperature of 150~200℃, and in particular case, it is possible to be hardening for 4-24hours at normal temperature, and for 5minutes at 250℃.

3. Stability of Hardening Substance : If hardening type paste is being made cross link over 90%, it has chemical resistance in organic liquid such as acetone, and is has heating stability against change and decomposition under 200℃.

4. Paste Storing : In general, the storing conditions for hardening type paste are in indoor refrigerator under the temperature of 5~10℃ without direct ray of light. In specific case, it could be stored in under below -10℃. It shall be stored in lower humidity without direct ray of light and radiant heat after effusion in the refrigerator.

5. Cautions for Handling of Curing Type Paste

1) After effusion of paste in refrigerator, it shall be leaved in normal indoor temperature for 2-3hours without open.

2) Dew condensation shall be on the surface of Paste, and clean it with cloth and leave it in the normal temperature continuously.

3) Pleas open the Paste when the temperature is normal, and it shall be mixed for 30-60minutes by the mixer.

4) After mixing work, please make sure the paste by before the work.

(Please do not try to use the Paste which is lump together or not color evenly.)

5) The moisture could cause adhesive strength and pinhole, and thus attention on the paste temperature shall be made during rainy season or winter season.

6) In the event of increased level of paste viscosity, please use the diluent as designated.

7) After the work has finished, the remained paste shall be managed separately, and please check the lump together when it shall be used again. (More than twice of usage shall be prohibited.)

8) Please clean the clothes and skin after the work, because it contains composition to be injected into the skin.

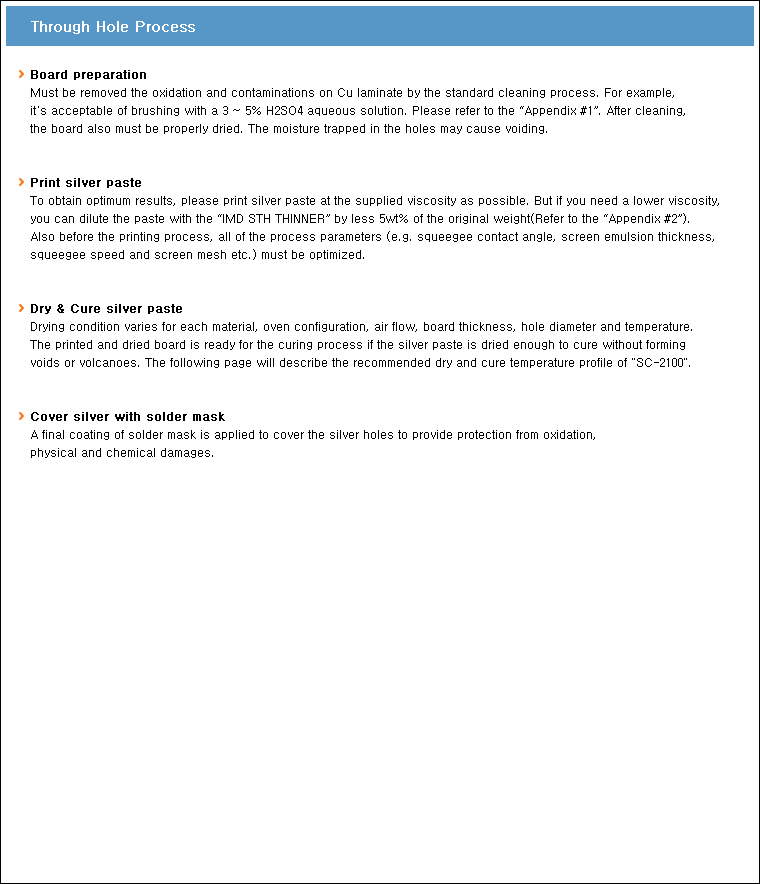

PCB Though Hole